This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Scientists open door to achieving high-precision 'slippery structural hydrogel'

Hydrogels inevitably undergo dehydration, structural collapse, and shrinkage deformation due to the uninterrupted evaporation in the atmosphere, thereby losing their flexibility, slipperyness, and manufacturing precision.

The research, published in International Journal of Extreme Manufacturing, shows how to manufacture a kind of slippery, soft material with high precision in which water molecules are prone to evaporation but still well implemented with high-fidelity structured functional materials.

But the finding could also be extraordinarily useful; if you want to invent something revolutionary, the process often first starts with discovering an entirely new material.

"In principle, this opens up the design and construction of a whole new class of soft matters that, wet and lubricating, are easy to shape and are resistant to dehydration in atmosphere conditions," said Xiaolong Wang, a professor of State Key Laboratory of Solid Lubrication at the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, and the senior author on the study.

"Essentially, it suggests new possibilities for extremely significant biolubricating materials and high-precision processing technologies," said Desheng Liu (Research assistant), the first author of the paper.

Hydrogel is a kind of soft material with a hydrophilic three-dimensional cross-linked network structure, which has been extensively applied in tissue engineering, wound dressings, flexible wearable devices, electronic skin, and soft robots due to their flexibility, mechanical tunability, biocompatibility, lubricity, and so on.

By far, the oldest approaches, such as hygroscopic salts and binary water-organic mixed solvents, have been introduced into the bulk hydrogels, restraining the water evaporation under ambient conditions by raising the enthalpy of vaporization of water. Despite improved dehydration tolerance, the hydrogels constructed by these means are inevitably liable to alter properties such as wettability, lubricity, mechanics, and even hydration.

This is advantageous because these materials are more flexible and difficult to process than traditional hard materials, but the trouble is they aren't very stable; they can lose their flexibility if exposed to air or if the temperature gets too high.

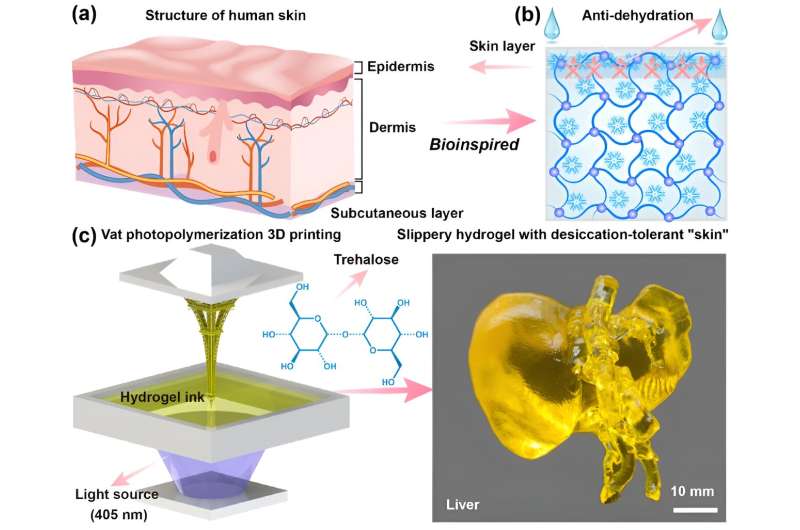

Given the biological structure of human skin for "water retention," herein the researchers report a novel bioinspired strategy that introduces trehalose into the hydrogel network to form trehalose-induced hydrogen bond interactions. The interaction between trehalose and water can generate the surface layer with dehydration tolerance in the atmosphere, which results in flexible and slippery hydrogels.

Then Liu began experimenting with some natural moisturizing factors materials discovered years ago, but largely ignored. He made trehalose into an aqueous solution to make hydrogel photosensitive inks and structured hydrogel materials and then began testing its desiccation properties. Thus, trehalose can also act as an effective water retention agent for hydrogels by introducing strong hydrogen bonding interactions to retain inherent properties in the atmosphere.

To the scientists' astonishment, the introduction of trehalose into hydrogel can significantly improve its dehydration resistance, lubrication performance, mechanical properties, and manufacturing accuracy. What's more, it was very stable.

"The strong covalent-like hydrogen bonding interactions formed by multitudinous hydroxyl groups on the trehalose molecule and numerous polar groups on the long polymer chains can confer superior ductility and desiccation-tolerant of slippery hydrogel," said Liu. That is enormously helpful for a slippery, soft material device that has to function in real-world environments.

But to the scientists, the most striking thing was that the soft material is water-contained.

"Combining vat photopolymerization 3D printing and trehalose-modified hydrogels can achieve the miscellaneous stereoscopic hydrogels with desirable resolution, complicated geometries, and tailorable microarchitectures at the macroscopic level due to overcoming the desiccation induced shrinkage and collapse deformation in manufacturing process," said Wang. "As a proof-of-concept demonstration, a high-precision hydrogel vascular phantom was created to imitate guidewire intervention."

The result is unprecedented for a slippery hydrogel material. "It's almost like human skin—you can effectively lock in dampness to prevent excessive evaporation, and thus possessing favorable dehydration tolerance," said Wang.

The scientists are excited because this discovery proposes a fundamentally new design principle for the high-precision manufacturing of hydrogel materials. Natural moisturizing factors are so important for hydrogel materials that almost any new soft material development will open up new frontiers for additive manufacturing techniques, they explained.

It is believed that the proposed method paves the way toward manufacturing large-scale structural hydrogels with dehydration tolerance in the atmosphere, broadening their applications in complex environments.

The team is also exploring the different structures and functions that hydrogel materials may produce by harnessing VAT photopolymerization 3D printing. "We think we proposed a convenient and versatile strategy adapts to manufacture large-scale hydrogels with sophisticated architectures in a long-term process," said Wang.

More information: Desheng Liu et al, Slippery hydrogel with desiccation-tolerant 'skin' for high-precision additive manufacturing, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/ad1730

Provided by International Journal of Extreme Manufacturing