This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Strategies for environmentally friendly and sustainable polyamide production

Global industries focused on carbon neutrality, under the slogan Net-Zero, are gaining increasing attention. In particular, research on the microbial production of polymers, replacing traditional chemical methods with biological approaches, is actively progressing.

Polyamides, represented by nylon, are linear polymers widely used in various industries such as the automotive, electronics, textiles, and medical fields. They possess beneficial properties including high tensile strength, electrical insulation, heat resistance, wear resistance, and biocompatibility.

Since the commercialization of nylon in 1938, approximately 7 million tons of polyamides are produced worldwide annually. Considering their broad applications and significance, producing polyamides through bio-based methods holds considerable environmental and industrial importance.

KAIST has announced that a research team led by Distinguished Professor Sang Yup Lee, including Dr. Jong An Lee and doctoral candidate Ji Yeon Kim from the Department of Chemical and Biomolecular Engineering, published a paper titled "Current Advancements in Bio-Based Production of Polyamides." The paper was featured on the cover of the monthly issue of Trends in Chemistry by Cell Press.

As part of climate change response technologies, bio-refineries use biotechnological and chemical methods to produce industrially important chemicals and biofuels from renewable biomass without relying on fossil resources. Notably, systems metabolic engineering, pioneered by KAIST's Distinguished Professor Sang Yup Lee, is a research field that effectively manipulates microbial metabolic pathways to produce valuable chemicals, forming the core technology for bio-refineries.

The research team has successfully developed high-performance strains producing a variety of compounds, including succinic acid, biodegradable plastics, biofuels, and natural products using systems metabolic engineering tools and strategies.

The research team predicted that if bio-based polyamide production technology, which is widely used in the production of clothing and textiles, becomes widespread, it will attract attention as a future technology that can respond to the climate crisis due to its environment-friendly production technology.

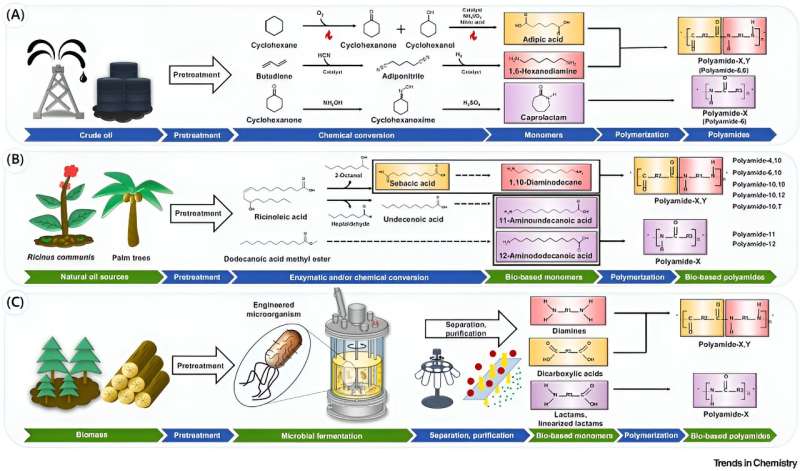

In this new study, the research team comprehensively reviewed the bio-based polyamide production strategies. They provided insights into the advancements in polyamide monomer production using metabolically engineered microorganisms and highlighted the recent trends in bio-based polyamide advancements utilizing these monomers.

In addition, they reviewed the strategies for synthesizing bio-based polyamides through chemical conversion of natural oils and discussed the biodegradability and recycling of the polyamides. The paper also presented future directions in which metabolic engineering can be applied for bio-based polyamide production, contributing to an environmentally friendly and sustainable society.

Ji Yeon Kim from KAIST, the co-first author of this paper, stated "The importance of utilizing systems metabolic engineering tools and strategies for bio-based polyamides production is becoming increasingly prominent in achieving carbon neutrality."

Professor Sang Yup Lee emphasized, "Amid growing concerns about climate change, the significance of environmentally friendly and sustainable industrial development is greater than ever. Systems metabolic engineering is expected to have a significant impact not only on the chemical industry but also in various fields."

More information: Jong An Lee et al, Current advancements in the bio-based production of polyamides, Trends in Chemistry (2023). DOI: 10.1016/j.trechm.2023.10.001

Journal information: Trends in Chemistry